Qingdao JCWY Environmental Protection Technology Co., Ltd.

Qingdao JCWY Environmental Protection Technology Co., Ltd.

Qingdao JCWY Environmental Protection Technology Co., Ltd.

Qingdao JCWY Environmental Protection Technology Co., Ltd.

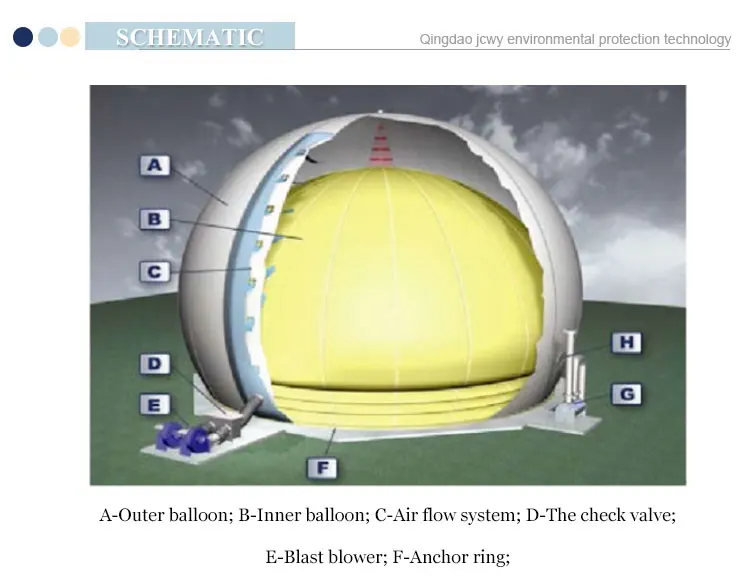

The double-film biogas holder is processed by using the film material and is divided into inner and outer layers and an additional base film.

The double-film biogas holder is processed by using the film material and is divided into inner and outer layers and an additional base film. The airtight space with a closed capacity variable between the inner membrane and the base membrane is mainly used for storing biogas. The outer membrane and the inner membrane are inflated by an external pressure control system to form a certain pressure ratio in the inner airbag. Then the biogas is sent out.

Volume size of fermentation tank | Power generating supporting

gas tank | |||||

Model(m³) | Diameter(m) | Height(m) | Effective volume(m³) | Total volume(m³) | Gas tank volume(m³) | Gas tank height(m) |

100 | 5.35 | 5.43 | 110 | 120 | 38 | 2.70 |

200 | 6.88 | 6.05 | 210 | 220 | 80 | 3.40 |

300 | 8.40 | 6.05 | 300 | 330 | 150 | 4.20 |

400 | 9.17 | 6.63 | 400 | 440 | 190 | 4.50 |

500 | 9.93 | 7.25 | 520 | 560 | 150 | 3.40 |

600 | 10.70 | 7.25 | 610 | 650 | 200 | 3.85 |

700 | 10.70 | 8.45 | 710 | 760 | 240 | 4.42 |

800 | 11.46 | 8.45 | 820 | 870 | 250 | 4.20 |

900 | 12.22 | 8.45 | 930 | 990 | 300 | 4.42 |

1000 | 12.99 | 8.45 | 1055 | 1150 | 350 | 4.60 |

Volume size of fermentation tank | Household type supporting

gas tank | |||||

Model(m³) | Diameter(m) | Height(m) | Effective volume(m³) | Total volume(m³) | Gas tank volume(m³) | Gas tank height(m) |

100 | 5.35 | 5.43 | 110 | 120 | 38 | 2.70 |

200 | 6.88 | 6.05 | 210 | 220 | 80 | 3.40 |

300 | 8.40 | 6.05 | 300 | 330 | 150 | 4.20 |

400 | 9.17 | 6.63 | 400 | 440 | 190 | 4.50 |

500 | 9.93 | 7.25 | 520 | 560 | 240 | 5.00 |

600 | 10.70 | 7.25 | 610 | 650 | 290 | 5.40 |

700 | 10.70 | 8.45 | 710 | 760 | 300 | 5.40 |

800 | 11.46 | 8.45 | 820 | 870 | 350 | 5.70 |

900 | 12.22 | 8.45 | 930 | 990 | 450 | 6.10 |

1000 | 12.99 | 8.45 | 1055 | 1150 | 500 | 6.50 |

2. The main component is a special

flexible film for corrosion resistance, which does not require any

anti-corrosion treatment.

3. Light weight, low infrastructure

requirements and low construction costs.

4. The biogas pressure is constant.

5. Short installation period and low

construction cost.

6. The product is lightweight, soft

and easy to transport.

7.With special materials, the

service life can reach 8-15 years.

As an emerging energy source, biogas is used

more and more widely. It can be used to heat boilers, produce steam for daily

life or industrial workshops, and can also be used for power generation in the

factory. Excess biogas can also be used as torch to Burned out. The

main industries used are:

1. Livestock farm;

2. Food processing plants;

3. Paper mill;

4. Chemical plant;